Desoldering Wick Application Guide

Solder wick, desoldering braid, or just “wick” are all names for a copper braid that is used to absorb solder. It is generally coated with flux, so when heated, solder is melted, drawn up, and retained using a combination of wetting and capillary action. Solder wick allows you to remove solder in isolated areas without thermally stressing the overall board or nearby components. Solder wick can only remove exposed solder, so components covering contact areas, like ball grid arrays (BGAs), have to be removed before the residual solder can be removed.

Instructions for Using Desoldering Wick:

Desoldering wick significantly reduces rework/repair time and minimizes the risk of heat damage to the board. Its geometrically precise weave design allows for maximum capillary action and solder capacity. Soder-Wick® Desoldering Braid optimizes heat transfer through the braid and into the solder joint, resulting in faster wicking action than any other competitive brand. Minimal flux residue on the board speeds up the cleaning process, or eliminates it entirely.

Desoldering with wick is quick and easy, requiring a standard solder iron and typically a screwdriver, chisel, bevel or knife soldering tip.

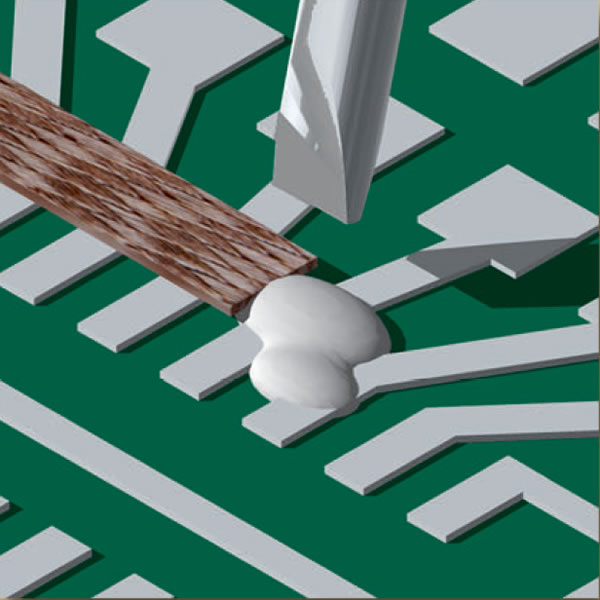

- Place the braid over unwanted solder, preferably on the greatest solder build up so that it maximizes the contact of the braid to the surface area of the solder.

- Next, place your iron tip over the wick at 45 degrees and allow heat to transfer to the pad. Molten solder will absorb into the braid.

- Move the solder tip and braid as needed to remove all of the solder at one time. Careful not to drag the braid over the pads, which can scratch.

- Once the braid is full of solder, you must trim the spent portion and move to fresh braid in order to pull more solder. Remove the iron and braid simultaneously to avoid soldering the wire to the board.

Desodering Wick Flux Types

Desoldering wick is available in a variety of flux types to allow users to best match rework and repair materials with the original assembly process. This can avoid cleaning issues, because PCBA cleaning processes are generally qualified and optimized with the original flux in mind.

Common types of flux coating on solder wick:

- Rosin – Rosin fluxed desoldering wick has the fastest wicking action but does leave behind residues that need to be thoroughly cleaned.

- No-Clean – No-clean fluxed desoldering wick is ideal when cleaning isn’t practical or possible. After desoldering, the only thing that remains is a clear, non-ionic residue. For field work, when a thorough cleaning is more challenging, this is the type of braid to use.

- Unfluxed – In a production or repair environment where the flux is specified and can’t be changed, or when an aqueous flux is needed, you can add your own flux to this type of braid. Unfluxed wick will not remove solder unless flux is added. Different types of fluxes are available in pen packaging, which is ideal for fluxing braid.

Solder wick can also be packaged in a variety of lengths. 5’ and 10’ lengths are handy for use at a work station. Static dissipative spools, also called “bobbins”, are available to prevent damaging components sensitive to ESD. Longer spools, like 25’ (7.6M), 50’ (15.2M), 100’ (30.5M) and 500’ (152.4M), are commonly stored in a more central location and dispensed to technicians as needed.

Other specialized braid designs are also available. For example, Chemtronics offers Soder-Wick Lead-Free, which is engineered to heat faster, so minimizing thermal shock for high-heat lead-free applications.

Standard Widths of Desoldering Wick

Solder wick comes in a wide variety of widths to efficiently remove solder from different types of contact areas. Choosing a desoldering wick width that closely matches the size of the contact area ensures that you get proper heat conduction and that you don’t desolder unwanted areas.

Wick that is too thin won't remove enough solder and requires you to trim and remelt the solder over and over. Wick that is too wide takes longer to heat and may interfere with other components on the circuit board.

Widths of desoldering wire are designated by the numbers 1 through 6 or color codes, which are the standard in the industry.

|

Size # |

Color code |

Width |

Typical application |

|

1 |

white |

.030"/0.8mm |

SMD, micro-circuits |

|

2 |

yellow |

.060"/1.5mm |

small pads, SMDs |

|

3 |

green |

.080"/2.0mm |

medium pads |

|

4 |

blue |

.110"/2.8mm |

large pads |

|

5 |

brown |

.145"/3.7mm |

terminals |

|

6 |

red |

.210"/5.3mm |

large lugs, BGA pads and chips |

Typical Desoldering Wick Applications

The combination of different fluxes and braid widths allow desoldering wick to be used is a wide variety of applications:

|

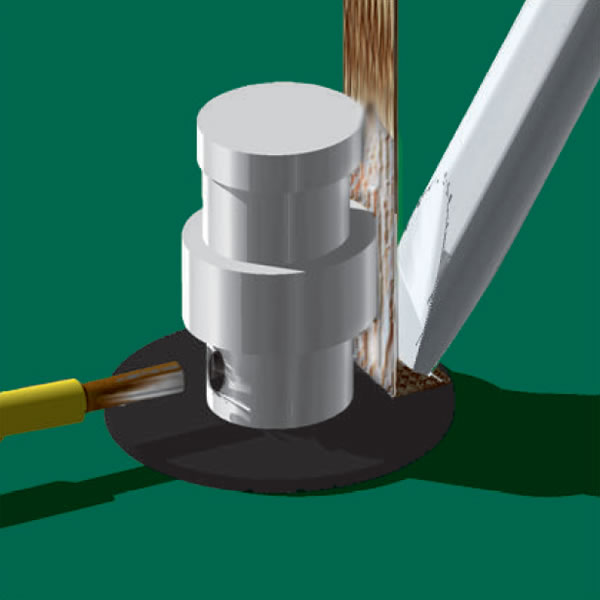

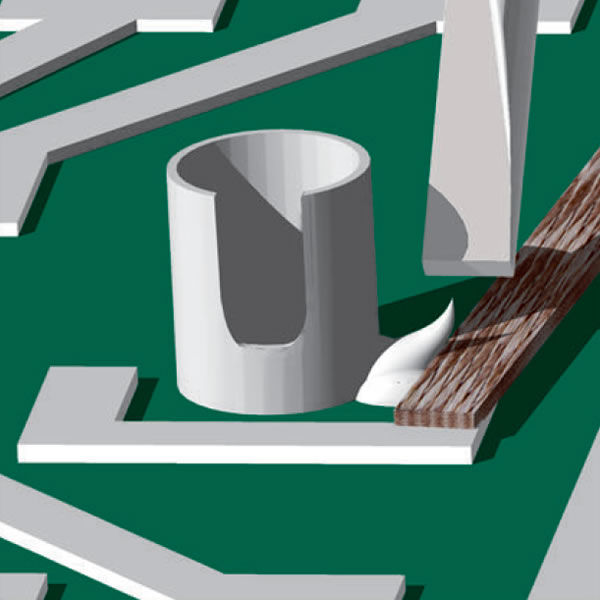

Wire Wrap Pins Desolder pins for easy removal. Removes solder buildup. Eliminates potential intermittent problems. |

|

|

Lugs/Posts Wicks solder completely, eliminating solder splash or drip. Leaves terminal fluxed and ready for resoldering. |

|

|

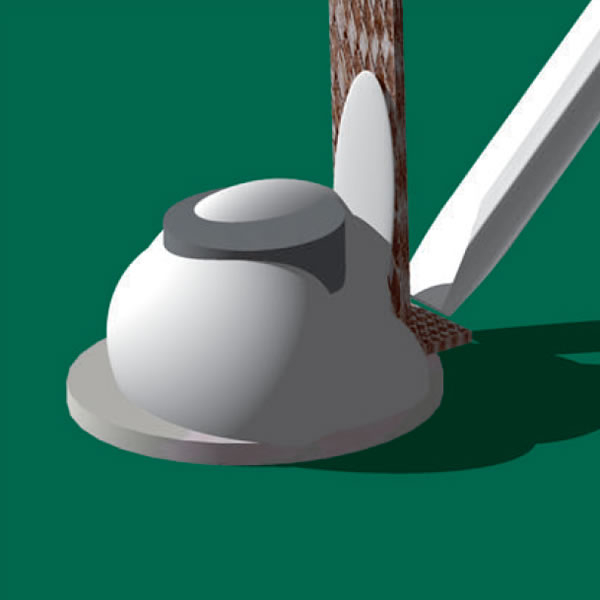

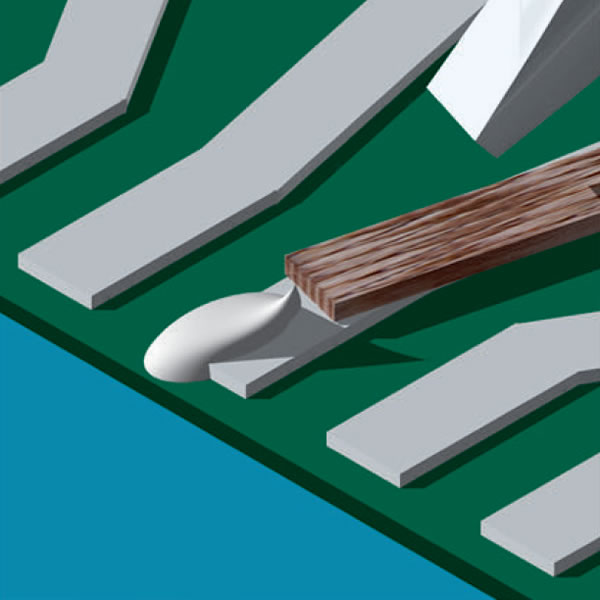

Components Easily removes solder from components with straight or clinched leads. Minimum heat required. No damage to board or components. |

|

|

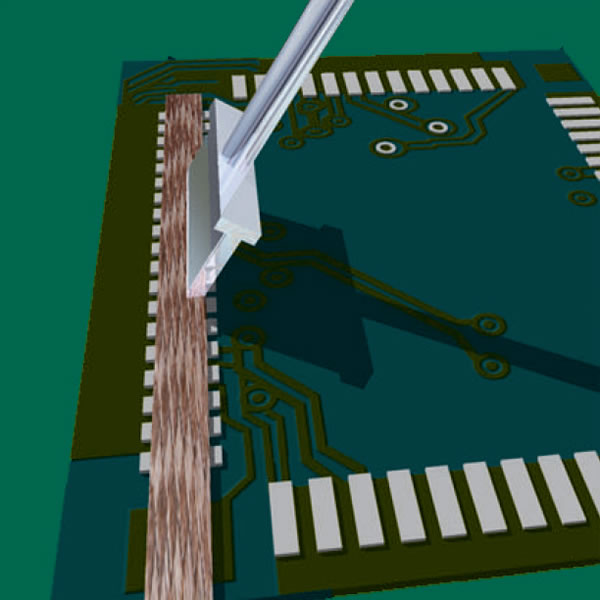

SMT Pads Quickly and safely desolders entire rows of SMT pads. Applications-specific sizes desolder individual fine-pitch SMT pads. |

|

|

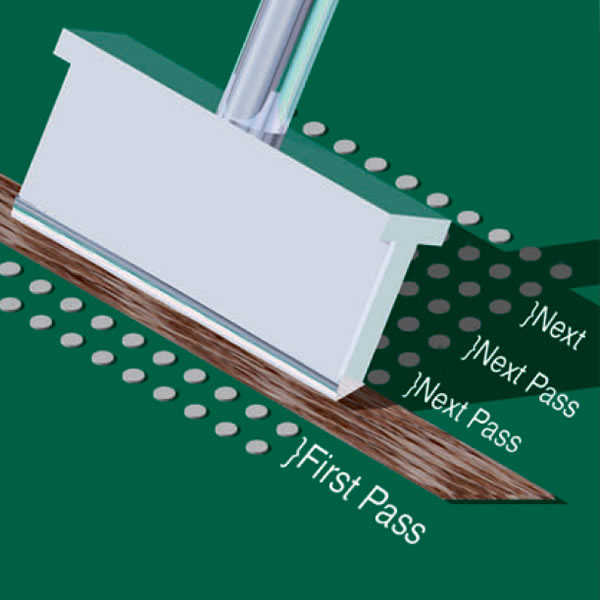

BGA Pads Safely removes solder from BGA pads and chips in three to four passes. Completely removes all residual solder and facilitates chip repositioning. |

|

|

Solder Bridges Completely removes solder bridges. Eliminates potential shorts. No damage to boards or circuitry. |

|

|

Clean Script Selectively retouches etched script. Improves aesthetic appearance. Eliminates secondary identification. Easy to use. |

|

|

Excess Solder Eliminates and removes blobs as well as shorts and icicles. Leaves circuitry smooth. Cleans potential problem areas. |

|

|

Finger Connectors Cleans finger connectors and surface mount pads. |

|

For more information, contact a technical specialist at askchemtronics@chemtronics.com or 678-928-5845.