The Combination Cleaning™ Guide for Fiber Optic Connector Cleaning

There’s a dirty little secret in the fiber optics world.

Many installers use cleaning methods that when inspected under a scope, show a great deal of contamination left behind.

Unless they inspect 100% of their connections, they take the chance of reduced signal strength cutting back on bandwidth. Many operators click their tools or wipe off the connectors with alcohol with confidence in their process, yet that process is letting them down.

To learn more about the less than satisfactory methods to clean fiber optic cables, check out our post How To Clean and How Not To Clean Fiber Optic Connectors.

But there's good news. The wet-to-dry Combination Cleaning™ process is the way to move beyond going through the motions, and effectively clean fiber-optic connectors the first time… every time.

The Importance of Wet-to-Dry Combination Cleaning™ for Fiber Optic Connectors

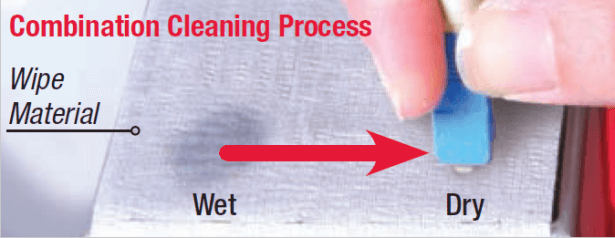

The Combination Cleaning method is a wet-to-dry cleaning method in which the amount of solvent used in the process is kept extremely small. This process recognizes that dry cleaning achieves suboptimal results and leaves the optical connector end face charged with an electrical field that is likely to attract contamination after the fiber optic cleaning process. It also recognizes that using too much solvent in the fiber optic cleaning process can lead to flooding the surface and cross-contamination.

The Combination Cleaning method can be used with wipes, swabs, and probe cleaning tools. In each case, the material is made slightly damp with an appropriate solvent. The end face is first exposed to the surface with solvent and then is dried using a surface without solvent. This action first enables the solvent to dissipate the static charge and dissolve contamination while the wipe or swab physically removes the soil from the surface. The wipe or swab then dries any remaining solvent from the surface so that remaining solvent cannot be used as a carrier for cross-contamination of surfaces. The specific process for each of the cleaning methods is explained in the next section of this paper.

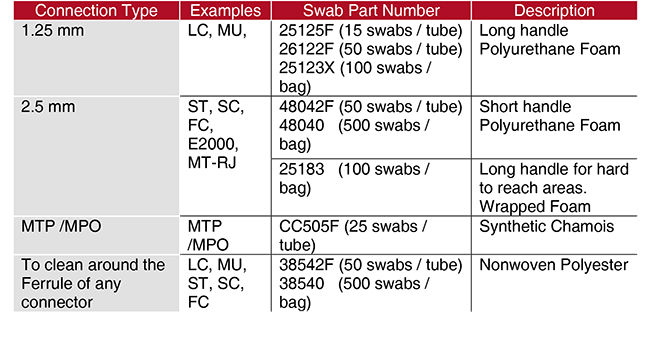

The specific cleaning products used will vary slightly depending on the type of connector that you are cleaning. 2.5 mm (ST, SC, or FC) connectors are cleaned with a different size tool and swab than a 1.25mm (LC, or MU) connector, for example. In every case, however, the basic concept is the same. Refer to this chart for the tools recommended for various types of fiber connectors.

Combination Cleaning Process: Place a drop of solvent (enough for a dime-sized spot) on the wipe, and then lightly draw in a straight line from the solvent over the dry wipe, removing the soils and drying the end face in one motion.

Choosing The Best Solvent for Fiber Optic Cleaning

Solvent Packaging: Good solvent packaging for fiber optics cleaning is sealed and portable. Hermetically sealed containers eliminate the opportunity for contamination of the cleaner and prevent accidental spillage. Portability assures that the solvent is not cumbersome to installers, and can easily be included in a fiber optic cleaning kit.

Pen Packaging: Solvent dispensing pens are an excellent way to apply solvent to clean fiber optic end faces. The pens employ a valve to protect the solvent from environmental contamination and leakage. When pressed onto a cleaning surface, the valve is automatically opened to release a small amount of solvent. The felt tip of the pen dispenses a small amount of solvent without splattering excess solvent. The pens fit easily into a tool bag or pocket.

Aerosol Packaging: An aerosol can of solvent is also a good way to deliver solvent to cleaning surfaces. Aerosols are also hermetically sealed. While the containers are not quite as portable as a pen, the increased size enables them to hold cleaner, reducing costs and adding convenience for large cleaning jobs.

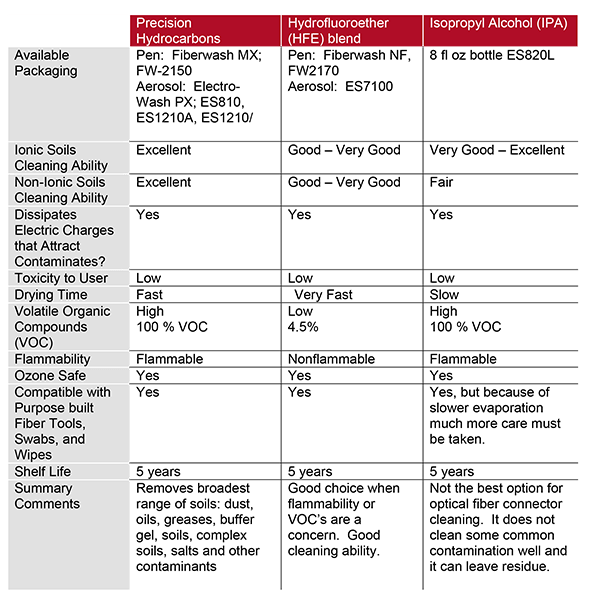

Solvent Choice: Using a solvent significantly improves the performance of the optical fiber connector cleaning process. Isopropyl alcohol (IPA) is not recommended in this application because of its poor solvency and because of its tendency to leave a residue.

Excellent alternatives exist. The most widely used precision solvents for fiber optic cleaning are precision hydrocarbons. These fiber optic connector cleaners perform well on a wide range of soils and eliminate static electrical charges which could attract contamination after cleaning. They evaporate quickly and have low toxicity. The single drawback is that the chemistry is flammable. Considering that the quantities used are relatively small, storage and safety concerns from this flammability is usually minimal. Recommended products are the Fiberwash™ MX pen and Electro-Wash® PX in an aerosol package.

For those requiring a non-flammable fiber optic cleaner, a hydrofluoroether (HFE) blend solvent is an excellent choice. These solvents are non-flammable, clean fiber connectors well, and have low toxicity. Cleaning must be done quickly, as the evaporation rate is very fast. Recommended products are the Fiberwash NF pen and Electro-Wash CZ in an aerosol package.

Solvent Types for Fiber Optic Cleaning

The Three Best Fiber Optic Cleaning Tools

The choice of cleaning tools depends on the types of connectors to be cleaned and the accessibility of those connectors. CCT Clear Connection Tools are the easiest to use and are capable of cleaning both unmated male connectors and recessed connectors. That does not mean, however, that wipes and swabs no longer demand a place in an installer’s toolkit. QBE Cleaning Platforms remain the most effective method of cleaning unmated male connectors, and swabs remain the most effective method of cleaning connectors that remain in an alignment sleeve. Regardless of which tool is chosen, always use the wet to dry method to ensure the best cleaning result.

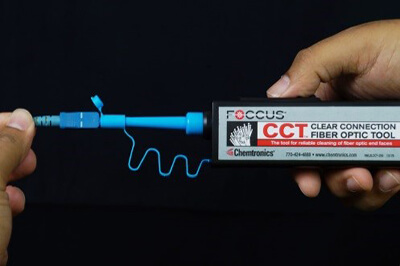

The CCT Clear Connection Tool uses an automated wiping process to easily clean contamination from connection end faces. The tool is especially convenient when cleaning large quantities of end faces through bulkhead adapters. This cleaning method is easy to learn and enables the cleaning of multiple ports in a short period of time. CCT tools have an easy to use

To clean connectors inside of bulkhead adapters, remove the dust cap from the end of the CCT tool. Lightly wet the CCT fabric tip with a Fiberwash pen, and then insert the CCT tip directly into the connector. Push in the tool 2-3 clicks, advancing the fabric from wet-to-dry. The fabric rotates while advancing, adding additional cleaning action. Check your work with a fiberscope, OTDR, or other inspection instruments. Repeat on the next connector until all connectors have been cleaned.

The end faces of unconnected patch cords can be cleaned by placing the dust cap back onto the end of the CCT tool and opening the end of the cap. The dust cap becomes an adapter that fits directly over the ferrule of the connector. Push the tool 2-3 clicks to advance the fabric and clean the end face. Again, adding a small amount of solvent to the fabric before each cleaning is recommended to maximize cleaning ability. Check your work with a fiberscope, OTDR, or other measurement instruments.

Choose the correct CCT tool to match the connector.

o CCT-250 is used to clean all 2.5mm connectors, including FS, SC, and ST.

o CCT-125 is used to clean all 1.25 mm connections, including MU and LC.

o CCT-MPO is used to clean MPO connections.

Patented QBE Cleaning Platforms are the best cleaning tool for unmated male connectors. QBE’s are a portable and durable package of lint-free wipes with an attached neoprene cleaning surface under the wipes, perfect for fiber end face cleaning. QBE’s provide a large cleaning surface ideal for the Combination Cleaning method.

To use the QBE,

- Pull a wiper up and out of the box and place the wipe over the foam platen on the side of the box.

- Choose a solvent from the chart above to use in conjunction with the QBE. The most popular solvents are Fiberwash MX Precision Cleaner Pen for a pen application and Electro-Wash PX for the aerosol packaging. Using solvent eliminates electrostatic charge that can be generated any time two dry surfaces are rubbed together. Use a Fiberwash pen or aerosol to place one inch (2.5 cm) dot of solvent at one corner of the platen.

- Hold the end face perpendicular to the platen and glide the end face in a straight line over the wipe, pulling the end face in a long stroke from the spot of solvent to a dry area three times without retracing the same spot on the wipe. (Hold the connector at the same angle as the end face for APC connectors). Do not twist the end face or use a figure eight motion to clean, as these actions have the potential to damage the end face.

- Check your work with a fiberscope, OTDR, or other inspection instruments.

The QBE is available in four configurations:

o QBE: The original QBE is a 3” x 3” x 3” cube with a flat platen and 200 wipes. It is ideal to clean any connector with an exposed end face.

o QBE-R is the same as the QBE, except that it has grooves in the neoprene platen to clean connectors with alignment pens that extend beyond the ferrule’s end face.

o QBE-2 is a 1.5” x 3” version of the QBE with a lanyard to attach the box to your belt. It does not have grooves in the platen.

o PQBE, or “Pocket QBE” is the same size as the QBE-2, except with grooves in the platen to clean connectors with alignment pens that extend beyond the ferrule’s end face.

Fiber Optic Cleaning Swabs

Cleaning swabs are an excellent cleaning tool for inaccessible fiber optic connectors on the backplane while it is still connected to the alignment sleeve. They continue to be the most dependable cleaning method in these applications. Swabs are also a good cleaning solution for any fiber optic connector or crevice that is not reachable with a CCT Tool or QBE.

When possible, disconnect the plug from the backplane and clean the fiber optic cable using a QBE and the combination cleaning method. Additionally, clean the alignment sleeve with a small amount of solvent and the appropriate swab in order to avoid cross-contaminating the plugs.

When disconnecting the backplane connector is not possible, a Chemtronics FOCCUS swab is the most effective cleaning method to clean the plugs in place.

- Choose the appropriate swab based on the size of the connector and the application.

Choose a solvent from the chart above to use in conjunction with the swab. The most popular solvents are Fiberwash MX Precision Cleaner Pen for a pen application and Electro-Wash PX for the aerosol packaging. Using solvent eliminates electrostatic charge that can be generated any time two dry surfaces are rubbed together.

- Spot a small amount of solvent on to a QBE wipe. Dab/tap the swab onto the wetted area. Hold the tip of the swab in the moist area for a count of 1-2-3-4-5. The solvent saturated tip of a pen can also be held directly to the swab in a similar manner. Do not saturate the swab. Excessive solvent could carry contaminants to other surfaces.

- Insert the swab into the connector, press lightly against the connector, twist 2-3 times and remove.

- Dry with a second swab.

- Check your work with a fiberscope, OTDR, or other measurement instruments.

Fiber optic connections should always be inspected and cleaned when necessary before connecting. Cleaning connectors dry yields inferior cleaning results and put an electric charge on the connector which may attract more contamination. Isopropyl alcohol (IPA) is a poor fiber optic cleaner of common contaminants and its slow evaporation can cause the connector to pull outside contamination into the connection when mating.

The preferred method for connector cleaning is to use a small amount of solvent to dissolve the soil, and then to dry the connector surface. This is done most effectively using a combination cleaning method, which combines the solvent and drying procedure. This method is effective for use with CCT Clear Connection Tools, QBE Cleaning Platforms, and

So the secret is out! Spread the word about wet-to-dry Combination Cleaning so all installers can clean