Wet to Dry Combination cleaning for Fiber Optic Connectors

There’s a dirty little secret in the Fiber optics world. Many installers use cleaning methods that when inspected under a scope, show a great deal of contamination left behind.

Unless they inspect 100% of their connections, they take the chance of reduced signal strength cutting back on bandwidth. Many operators click their tools or wipe off the connectors with alcohol with confidence in their process, yet that process is letting them down.

The wet-to-dry Combination Cleaning™ process is the way to move beyond going through the motions, and effectively clean fiber-optic connectors the first time… every time.

The Importance of Wet-to-Dry Combination Cleaning™ for Fiber Optic Connectors

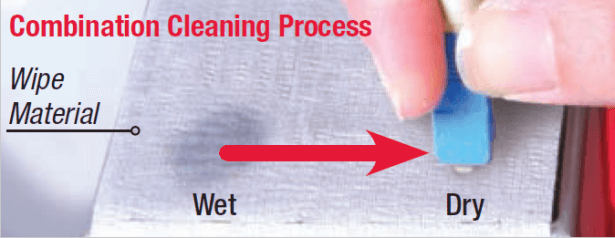

The Combination Cleaning method is a wet-to-dry cleaning method in which the amount of solvent used in the process is kept extremely small. This process recognizes that dry cleaning achieves suboptimal results and leaves the optical connector end face charged with an electrical field that is likely to attract contamination after the fiber optic cleaning process. It also recognizes that using too much solvent in the fiber optic cleaning process can lead to flooding the surface and cross-contamination.

The Combination Cleaning method can be used with wipes, swabs, and probe cleaning tools. In each case, the material is made slightly damp with an appropriate solvent. The end face is first exposed to the surface with solvent and then is dried using a surface without solvent. This action first enables the solvent to dissipate the static charge and dissolve contamination while the wipe or swab physically removes the soil from the surface. The wipe or swab then dries any remaining solvent from the surface so that remaining solvent cannot be used as a carrier for cross-contamination of surfaces. The specific process for each of the cleaning methods is explained in the next section of this paper.

The specific cleaning products used will vary slightly depending on the type of connector that you are cleaning. 2.5 mm (ST, SC, or FC) connectors are cleaned with a different size tool and swab than a 1.25mm (LC, or MU) connector, for example. In every case, however, the basic concept is the same. Refer to this chart for the tools recommended for various types of fiber connectors.

Combination Cleaning Process: Place a drop of solvent (enough for a dime-sized spot) on the wipe, and then lightly draw in a straight line from the solvent over the dry wipe, removing the soils and drying the end face in one motion.