How To Clean and How Not to Clean Fiber Optic Connectors

Why is it important to clean fiber optic connectors?

The ability to transmit enormous amounts of data over long distances in a flash is a distinct advantage of fiber optic cables. Fiber installers; however, must ensure that contamination on the fiber connectors is minimized in order to stay within the acceptable range of data loss. Oil and dust particles small enough to be invisible to the naked eye are large enough to block the entire 9-micrometer core diameter of a single mode fiber. Smaller soils increase signal attenuation and return loss and have the potential to cause permanent damage to the connectors.

Contact us regarding your specific fiber optic cleaning challenges, and we'll work with you to create a solution. If you're deciding on the what is the best cleaning tools to use for your application, check out our combination cleaning guide.

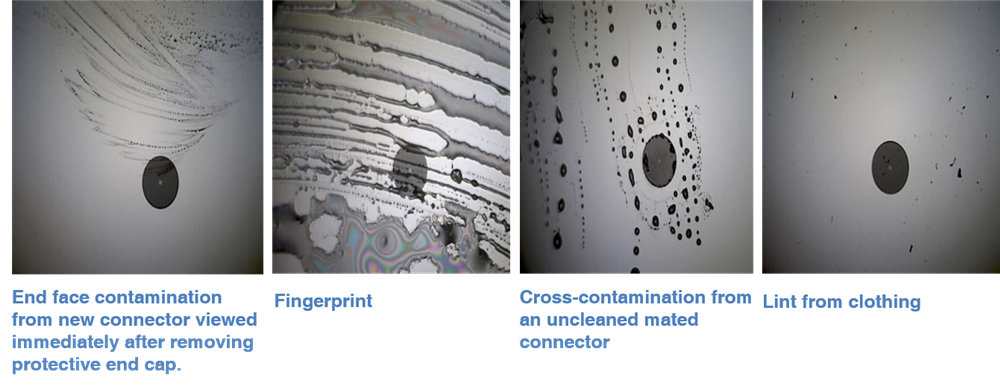

Below are examples of the impact of fiber contamination:

- A major telecom company found that 16 percent of connectors in their fiber-to-the-home network was sufficiently contaminated to cause performance problems (Sheedy, 2014)

- A survey of contractors found that contaminated end-faces were the cause of 85% of fiber link failures (Lang & Carter, 2016)

- An electronics industry association, IPC, found that contamination is the most common cause of degradation in the performance of optical connectors (IPC-8497-1, 2005, p. 7)

- The International Electrotechnical Commission states that contamination remaining on a plug’s end face has a tendency to migrate towards the core when mating, impeding light transmission (IEC/TR 62627-01, 2010, p. 8)

- SAE Aerospace found that mating contaminated end faces can create pits or result in embedded particulates in the ferrule or fiber, causing permanent damage (SAE AIR6031, 2012, p. 13)

You can’t assume that new connectors out of the package will be sufficiently clean. Sources of contamination include the hands and clothing of those handling the connections, building materials, dust, pollen, oil, sawdust, airborne contaminants, and more. Even the dust caps used to protect the ferrule can contaminate the connector’s end face.

Most contaminants are impossible to see without the aid of a microscope; keep in mind that the fiber core is several times smaller than a human hair. Furthermore, the act of mating and de-mating connectors causes dust particles outside of critical areas to accumulate and redistribute onto the connector end face (TIA-455-240, page 19). Additionally, mating a dirty plug cross contaminates the other plug. It is critical to inspect and when necessary clean every connection every time it is mated, including unmated plugs which were previously found to be clean.

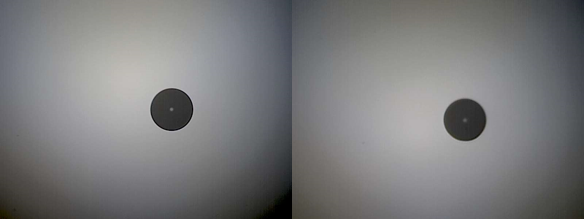

The first two pictures of are a microscopic view of two recently cleaned connectors. After cleaning, the connectors were mated and unmated five times.

The following pictures show contamination in critical areas after the mating and unmating of the connectors previously shown to be clean.

Proper inspection and cleaning process

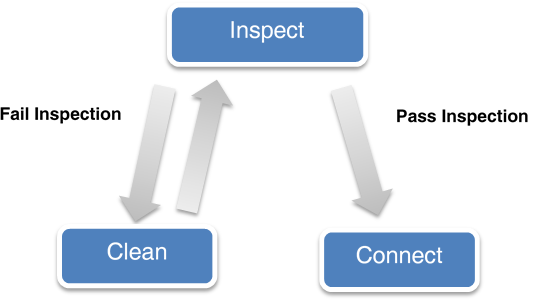

Fiber connector cleaning is an essential part of quality fiber installations. It is essential to inspect every fiber optic connection before every mating and to clean those connections when necessary.

An effective fiber optic connector cleaning process must be effective on a wide variety of contamination and provide the best possible result every time. International standard IEC 61300-3-35 outlines industry accepted inspection criteria for contamination and defects on the end face of the connector. When the connector fails this inspection or when equipment to test the connection is not available, the plug should be cleaned using the Combination Cleaning Process. Inspect the connector again, and make the connection when the plug passes inspection.

Proper inspection and cleaning process

Unreliable Cleaning Methods: How to Not Clean Your Fiber Connectors

Inferior cleaning processes create more hassles in the field and can lead to less reliable networks. Three common but unreliable cleaning methods are dry cleanings, cleaning with isopropyl alcohol, and wet cleaning.

Dry Cleaning Connectors

Cleaning optical connectors with a dry wipe or swab is a common but risky means of cleaning an optical connector. It is much more difficult to remove soils dry than wet, i.e. with a solvent that breaks down the soils and aids in their removal. Additionally, the act of dry wiping creates a static charge that can attract contamination after the connector is cleaned (IEC/TR 62627-01, 2010, p. 11). Laboratory tests demonstrate the attraction of metallic powder to optical connectors electrically charged by wiping them dry on the fabric of a typical cassette style fiber optics cleaner (Berdinskikh, Fisenko, Daniel, Bragg, & Phillips, 2003). Similar contamination occurs in practice as the end face is placed near any uncleaned surface after being cleaned with a dry cleaning process.

The static charge resulting from dry cleaning can be reduced by exposing the cleaned connector end face to deionized air for 5 to 10 seconds after the cleaning process. A simpler solution, however, is to clean using static dissipative solvents in conjunction with the cleaning materials (TIA-455-240, 2009, p. 18). Using purpose-built wipes and swabs in conjunction with solvents engineered to clean optical surfaces adds chemical cleaning action and eliminates the problem of static generation (IEC/TR 62627-01, 2010, p. 11).

Cleaning Fiber Optic Connectors with Isopropyl Alcohol

Each of the industry’s technical guidelines for cleaning optical connections expresses caution when using isopropyl alcohol (IPA) for cleaning connector end faces. Unfortunately, most operators are unaware that using IPA in this application requires careful attention to avoid further contaminating the end face surface.

The first issue is that IPA is not an effective cleaner for the wide range of soils that may contaminate optical connections. It is a poor solvent for some of the common soils found in optical fiber installation, such as buffer gels and oils (Blair, 2006). It also has a tendency to leave a residue when cleaning is not followed by a dry clean with a wipe or swab (IPC-8497-1, 2005, p. 15).

The second issue is that IPA is a comparatively slow evaporator and therefore less likely to have evaporated completely when the connector is mated. IPA is hygroscopic so that even high purity IPA will eventually attract water and other impurities; further slowing its evaporation rate. Mating the fiber connectors creates a capillary action that pulls the impure solvent into the mated area (Blair, 2006). The end result is often a “halo” of contamination on the end face of the connector.

Wet Cleaning with Excessive Solvent

Using excessive solvent in optical fiber connector cleaning has its own set of pitfalls. Overuse of solvent can result in flooding the side of the ferrule, leading to cross-contamination of the end face after cleaning (Telcordia — GR-2923-CORE, Issue 2, 2010, pp. 2-8). In this case, using more of a cleaner does not improve the cleaning ability of the process. Very little solvent is required to break the static charge and dissolve the soils on the end face. Too much solvent was used if any solvent is still detectable under a microscope immediately after the cleaning process. Good optical fiber cleaners are engineered so that very little fluid is required, and so that they evaporate very quickly. Using these solvents appropriately is described below.

Combination Cleaning: The Best Fiber Cleaning Method

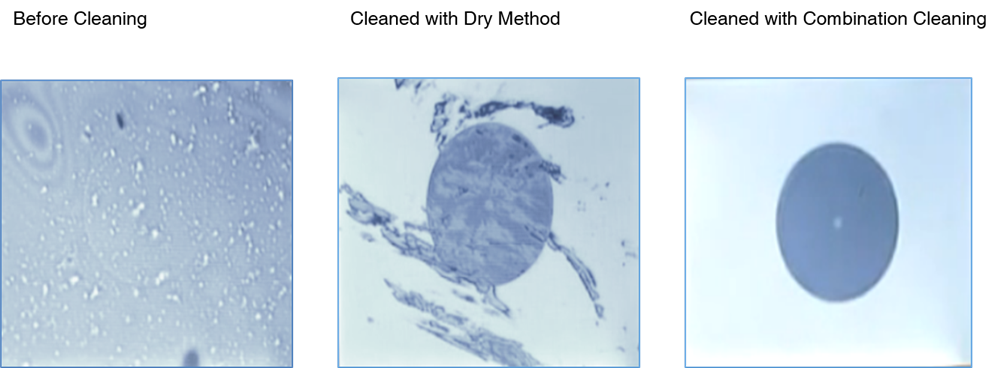

The following is an end face that was contaminated with a sharpie marker to test cleaning.

The combination cleaning method is a form of wet to dry cleaning in which the amount of solvent used in the process is kept extremely small. This process recognizes that dry cleaning achieves suboptimal results and leaves the optical connector end face charged with an electrical field that is likely to attract contamination after the cleaning process. It also recognizes that using too much solvent in the “wet to dry” cleaning process can lead to flooding the surface and cross-contamination. The combination cleaning method uses a small amount of solvent but leaves the connector surface dry.

The combination cleaning method can be used with wipes, swabs, and fiber cleaning tools. In each case, the material is made slightly damp with an appropriate solvent. The end face is first exposed to the surface with solvent and then is dried using a surface without solvent. This action first enables the solvent to dissipate the static charge and dissolve contamination while the wipe or swab physically removes the soil from the surface. The wipe or swab then dries any remaining solvent from the surface so that remaining solvent cannot be used as a carrier for cross-contamination of surfaces. This is demonstrated in the image below.

The Combination Cleaning Process:

- Place a drop of solvent (enough for a dime-sized spot) on the wipe, and then lightly draw in a straight line from the solvent over the dry wipe, removing the soils and drying the end face in one motion.

- Debris and contamination are moved away from the initial point of contact in a straight line.

- Avoid figure 8 motions and twisting or turning motions, as these can redeposit contaminants or grind debris into the end face.

- Avoid hard-backed surfaces, as they can also grind debris into the end face

The same concept can be applied to cleaning with other tools designed for fiber cleaning: wipes, swabs, and CCT tools. The specific use of the combination cleaning method with each of these tools will be discussed in the next writing.

Many common techniques used in fiber optics cleaning give inconsistent results and can promote recontamination. Dry cleaning, cleaning with isopropyl alcohol, and wet cleaning of connectors provide poor results. The best fiber optic connector cleaning method is the combination cleaning method. This technique involves using a small amount of solvent on a wiping material and immediately drying the surface. Comment below your experiences using the combination cleaning method, or share your experiences using other methods -we'd love to have your feedback.

Works Cited

Berdinskikh, T., Fisenko, A. I., Daniel, J., Bragg, J., & Phillips, D. (2003). The role of electrostatic charge effect on the contamination of fiber optics connectors and the ways of eliminating it. Proc. SPIE 4833, Applications of Photonic Technology 5 (pp. 5-6). Quebec City, Canada: https://doi.org/10.1117/12.475352.

Blair, P. (2006, December 13). The Halo Effect on Fiber Optic End Faces: Cause and Prevention. Retrieved July 30, 2018, from Chemtronics' website: https://www.chemtronics.com/Content/Images/uploaded/documents/HaloEffect.pdf

IEC 61300-3-35. (2015, June). Fiber optic interconnecting devices and passive components – Basic test and measurement procedures – Part 3-35: Examinations and measurements – Visual inspection of fiber optic connectors and fiber-stub transceivers. IEC. Geneva, Switzerland: International Electrotechnical Commision.

IEC/TR 62627-01. (2010, August). Fiber optic interconnecting devices and passive components – Part 01: Fibre optic connector cleaning methods. International Electrotechnical Commission. Geneva, Switzerland: IEC.

IPC-8497-1. (2005, December). Cleaning Methods and Contamination Assessment for Optical Assembly. IPC. Bannockburn, IL, U.S.A.: IPC.

Lang, H., & Carter, C. (2016, May 24). Fiber’s Dirty Secret. Retrieved July 30, 2018, from ISE ICT Solutions & Education: https://www.isemag.com/2016/05/fibers-dirty-secret/

SAE AIR6031. (2012, April). Aerospace Information Report. SAE Aerospace. SAE.

Sheedy, S. (2014, August 1). The Importance of Properly Cleaning Fiber During Termination. Cabling Installation and Maintenance Magazine.

Telcordia — GR-2923-CORE, Issue 2. (2010, February). Generic Requirements for Fiber Optic Connector Cleaning Products. Telcordia Network Product Integrity (NPI) Division. Piscataway, NJ, U.S.A.: Telcordia Technologies, Inc.

TIA-455-240. (2009, September). Fiber Optic Connector Endface. TIA Standard. Arlington, VA, U.S.A.: Telecommunications Industry Association Standards and Technology Department.